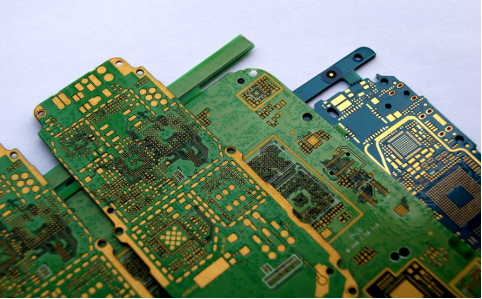

Consigned PCB Assembly: How It Works and When to Use It

In the world of printed circuit board (PCB) manufacturing, different assembly methods cater to diverse project requirements. Among these, consigned PCB assembly offers a unique approach that gives customers greater control over the components used in their designs. This method has proven invaluable in specific scenarios where customization, cost control, or proprietary requirements are crucial. In this blog, we’ll explore how consigned PCB assembly works, its advantages, and when it is the ideal choice for your project.

What Is Consigned PCB Assembly?

Consigned PCB assembly is a manufacturing process in which the customer provides all or most of the components required for assembling the PCBs. The contract manufacturer (CM) is responsible for assembling the components onto the board, ensuring quality and functionality. In this arrangement, the customer retains ownership and control of the components, which they procure themselves based on the design and project specifications.

This model contrasts with turnkey PCB assembly, where the manufacturer manages both the procurement of components and the assembly process. Consigned PCB assembly is particularly popular with businesses that have unique sourcing needs or want to oversee specific aspects of their supply chain.

How Does Consigned PCB Assembly Work?

The process begins with the customer selecting and supplying components for the assembly. These components include everything from integrated circuits (ICs) and resistors to connectors and custom parts. Once the parts are procured, the customer sends them to the assembly facility along with detailed documentation, such as the bill of materials (BOM), PCB design files, and assembly instructions.

Upon receiving the components, the manufacturer conducts an inventory check to ensure all required parts are available and in good condition. Any discrepancies or damages are communicated to the customer to resolve before proceeding. The actual assembly process involves mounting the supplied components onto the PCB using techniques like surface-mount technology (SMT) or through-hole technology, depending on the design. After assembly, the boards undergo testing and inspection to verify their functionality.

Advantages of Consigned PCB Assembly

One of the primary benefits of consigned PCB assembly is the level of control it offers. Customers can handpick components based on their preferences, specifications, or supplier relationships, ensuring compatibility with their design. This control is especially valuable for businesses working on proprietary or sensitive projects, as they can maintain confidentiality over specific components.

Cost efficiency is another advantage. Companies with access to discounted components or preferred suppliers can save significantly on procurement costs. Additionally, consigned assembly reduces the manufacturer’s workload in sourcing parts, which can translate to lower assembly charges.

Flexibility is also a key factor. Customers can supply specialized or hard-to-find components that the manufacturer may not typically stock. This approach is ideal for projects requiring rare parts, customized designs, or legacy components no longer in regular production.

When to Use Consigned PCB Assembly

Consigned PCB assembly is an excellent choice in several scenarios. For businesses working on highly specialized or sensitive projects, this method allows them to retain control over critical components. Industries like aerospace, defense, and medical devices often prefer consigned assembly to ensure that specific quality standards and certifications are met.

This method is also suitable for organizations with well-established supply chains. Companies with existing relationships with trusted component suppliers can leverage these connections to source parts at competitive prices while ensuring their quality and authenticity.

Projects involving custom or non-standard components are another area where consigned PCB assembly excels. Manufacturers might not have access to certain proprietary parts or rare components, making it necessary for the customer to provide them.

Additionally, consigned assembly works well for businesses managing small-scale production or prototype runs. For these projects, the customer might already have components on hand, eliminating the need for additional procurement.

Challenges in Consigned PCB Assembly

While consigned PCB assembly offers significant advantages, it also comes with certain challenges. One of the primary concerns is the risk of component shortages or delays. If the customer fails to supply all required parts on time, the assembly process can be delayed, impacting overall project timelines.

Another potential issue is ensuring the quality and compatibility of components. Customers must thoroughly inspect and verify their parts before sending them to the manufacturer to avoid problems during assembly. Additionally, managing the logistics of component procurement, packaging, and shipment requires careful planning and coordination.

Finally, working with multiple suppliers can sometimes lead to inconsistencies in component quality or specifications. Businesses must maintain strict quality control measures to ensure that all parts meet the required standards.

Conclusion

Consigned PCB assembly offers a tailored approach to manufacturing that prioritizes customer control and flexibility. It is an ideal choice for projects requiring specialized components, strict cost management, or proprietary designs. By allowing customers to manage the sourcing of components while leveraging the expertise of professional assemblers, this method strikes a balance between customization and efficiency.

However, success in consigned PCB assembly relies on careful planning, thorough documentation, and effective communication with the manufacturer. When executed correctly, it ensures high-quality PCBs that meet the unique demands of each project. Whether you’re working on prototypes, niche applications, or large-scale production, consigned PCB assembly provides the adaptability needed to bring your designs to life.