Seamless Production Process for Custom Printed Pouches

In today’s fast-paced consumer-driven market, packaging plays a crucial role in product presentation, brand recognition, and consumer appeal. As brands strive to differentiate themselves from competitors and meet the evolving demands of eco-conscious consumers, customized packaging solutions have become increasingly popular. Among these solutions, custom printed pouches stand out for their versatility, convenience, and eco-friendly attributes. In this article, we’ll explore the seamless production process behind custom printed pouches, highlighting their role in eco friendly packaging.

Understanding Flexible Packaging

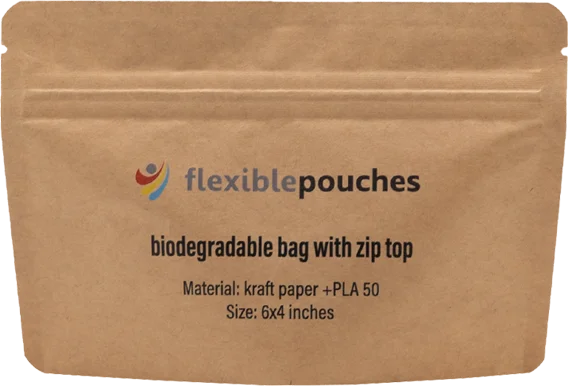

Flexible packaging refers to packaging materials that are pliable and easily adaptable to various shapes and sizes. It includes a wide range of products such as pouches, bags, wraps, and films, offering versatility and convenience for both manufacturers and consumers. Flexible packaging is lightweight, durable, and often requires fewer resources to produce compared to traditional rigid packaging, making it a preferred choice for many brands. Additionally, flexible packaging is well-suited for customization, allowing brands to incorporate unique designs, branding elements, and product features to enhance shelf appeal and consumer engagement.

The Rise of Custom Printed Pouches

Among the diverse array of FLEXIBLE PACKAGING options, custom printed pouches have gained popularity for their ability to combine functionality with aesthetic appeal. These pouches are commonly used for packaging a wide range of products, including snacks, beverages, pet food, personal care items, and more. Custom printed pouches offer brands the opportunity to showcase their logo, branding elements, product information, and eye-catching designs prominently, effectively capturing consumers’ attention and reinforcing brand identity. With advancements in printing technology and materials, custom printed pouches can now feature vibrant colors, intricate graphics, and high-quality finishes, enhancing product visibility and shelf presence.

The Seamless Production Process

The production process for custom printed pouches is a well-coordinated and streamlined operation, characterized by precision, efficiency, and attention to detail. While specific processes may vary depending on the manufacturer and the complexity of the pouch design, the following steps provide a general overview of the seamless production process:

Design and Prepress Preparation

The production process begins with the design phase, where brands work closely with packaging suppliers or manufacturers to develop custom artwork and packaging specifications. Once the design is finalized, it undergoes prepress preparation, where it is optimized for printing and converted into digital files compatible with printing equipment.

Printing

The printing process is where the magic happens. Custom printed pouches can be produced using various printing methods, including flexography, gravure printing, digital printing, and offset printing. Each method offers unique advantages in terms of print quality, color accuracy, and production speed. During printing, the custom artwork is transferred onto the pouch material using specialized printing presses, resulting in vibrant, high-resolution graphics that enhance shelf appeal and brand recognition.

Lamination and Coating

After printing, the pouch material may undergo lamination or coating processes to enhance durability, barrier properties, and overall performance. Lamination involves bonding multiple layers of material together to create a strong, flexible structure, while coating adds additional features such as gloss, matte, or specialty finishes. These processes not only protect the printed artwork but also contribute to the functionality and shelf-life of the pouch.

Conversion and Finishing

Once the printed material has been laminated and coated, it undergoes conversion into pouches through a series of cutting, sealing, and forming operations. Depending on the pouch style and specifications, these processes may include heat sealing, zipper application, spout insertion, and pouch forming. Precision and accuracy are critical during conversion to ensure that the pouches meet quality standards and specifications.

Quality Control and Inspection

Throughout the production process, quality control and inspection protocols are implemented to ensure that each custom printed pouch meets stringent quality standards. This may involve visual inspections, dimensional measurements, and performance testing to verify print accuracy, seal integrity, barrier properties, and overall functionality. Any defects or deviations are identified and addressed promptly to maintain product quality and consistency.

Packaging and Shipping

Once the custom printed pouches have passed quality control inspections, they are packaged according to customer requirements and prepared for shipping. Packaging may involve bulk packaging, labeling, and palletization to ensure safe and efficient transport to distribution centers or end-users. Timely delivery and logistics coordination are essential to meet customer deadlines and ensure product availability.

Eco-Friendly Packaging Initiatives

In addition to offering customization and functionality, custom printed pouches can also contribute to eco-friendly packaging initiatives. Many manufacturers offer sustainable pouch materials made from renewable, recyclable, or compostable resources, reducing environmental impact and supporting circular economy principles. These eco-friendly materials, combined with eco-conscious printing practices and production processes, help brands minimize their carbon footprint and meet consumer expectations for environmentally responsible packaging solutions.

Conclusion

The seamless production process for custom printed pouches exemplifies the intersection of innovation, efficiency, and sustainability in the packaging industry. From design and printing to conversion and finishing, each step is carefully orchestrated to deliver high-quality, customized pouches that meet the unique needs and branding objectives of brands. With the ability to incorporate vibrant graphics, branding elements, and eco-friendly materials, custom printed pouches offer brands a versatile and effective packaging solution for a wide range of products. As consumer preferences continue to evolve and sustainability becomes increasingly important, custom printed pouches will play a pivotal role in shaping the future of flexible packaging and eco-friendly initiatives.